Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

Cart

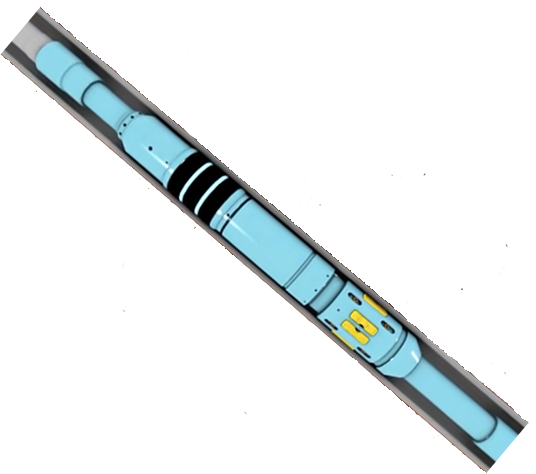

WI Valve for injection wells (3.39 inch)

The WI retrievable injection valve is a high-performance, high-flow rate injection valve. High throughput is achieved by a unique valve configuration that minimizes turbulent and potentially erosive flow. Operation is not dependent on a specific flow rate, pressure, or setting depth, thus negating the need for adjustment over time. The valve incorporates a metal-to-metal valve and seat energized by the combination of an integral spring and well pressure acting from below. The WI injection valve can be deployed on a wireline lock or through-tubing pack-off device, providing flexibility not available with alternative injection valve systems. As a result of the simple design with fewer parts, redress and repair costs are considerably lower than those for other injection valve systems. Applications The WI injection valve is primarily used in water injection applications as an alternative to conventional tubing or wireline-set safety valves. The valve is also commonly used as a retrofit solution in water injectors in which a tubing to annulus leak has occurred. The valve can be deployed below the leak point to eliminate uncontrolled annulus pressure increases when the injection stops. Features » Compatible with all known lock systems » Dedicated designs to suit Halliburton EB0 intervention packers » Enhanced internal flow profile » Simple design and construction » Flow-loop testing performed to establish pressure drop versus pump rate *information referenced from supplier catalog. View Details

SSV 4.51 inch for Water Injection Wells

The WI retrievable injection valve is a high-performance, high-flow rate injection valve. High throughput is achieved by a unique valve configuration that minimizes turbulent and potentially erosive flow. Operation is not dependent on a specific flow rate, pressure, or setting depth, thus negating the need for adjustment over time. The valve incorporates a metal-to-metal valve and seat energized by the combination of an integral spring and well pressure acting from below. The WI injection valve can be deployed on a wireline lock or through-tubing pack-off device, providing flexibility not available with alternative injection valve systems. As a result of the simple design with fewer parts, redress and repair costs are considerably lower than those for other injection valve systems. Applications The WI injection valve is primarily used in water injection applications as an alternative to conventional tubing or wireline-set safety valves. The valve is also commonly used as a retrofit solution in water injectors in which a tubing to annulus leak has occurred. The valve can be deployed below the leak point to eliminate uncontrolled annulus pressure increases when the injection stops. Features » Compatible with all known lock systems » Dedicated designs to suit Halliburton EB0 intervention packers » Enhanced internal flow profile » Simple design and construction » Flow-loop testing performed to establish pressure drop versus pump rate *information referenced from supplier catalog. View Details

Partner with Dunbridge Financial and Earn Commission

Join the Financial Revolution: Partner with Dunbridge Financial and Earn Commissions Along the Way Are you ready to be a part of something extraordinary? Dunbridge Financial is on a mission to revolutionize the international payments space, and we want you to join us on this exciting journey. As a valued business partner, you'll not only contribute to reshaping the financial landscape but also earn generous commissions while doing it. A Partnership Like No Other At Dunbridge Financial, we believe that success is best achieved together. We are looking for dynamic and forward-thinking partners who share our passion for providing awesome customer experiences through cutting-edge technology, competitive pricing, and unmatched convenience. Why Partner with Dunbridge Financial? 1. Earn Generous Commissions Your efforts won't go unrewarded. As a Dunbridge Financial partner, you'll have the opportunity to earn substantial commissions as we grow and expand our services. Your success is our success, and we're committed to recognizing your contributions. 2. Disrupting the Financial Landscape Dunbridge Financial is not just another player in the industry - we are disruptors. With our innovative approach to international payments, we are changing the game and setting new standards for customer satisfaction. 3. Cutting-Edge Technology Embrace the power of technology. By partnering with Dunbridge Financial, you'll have access to state-of-the-art tools and platforms that streamline transactions and enhance the overall customer experience. 4. Competitive Pricing We understand that affordability matters. Our competitive pricing ensures that our clients get the most value for their money, making us the preferred choice for businesses worldwide. 5. Unmatched Convenience Convenience is at the core of our services. With Dunbridge Financial, our clients can seamlessly send and receive money to over 100 countries, all from one elegant platform. Join us in providing unparalleled convenience to businesses and individuals across the globe. Join Our Journey to Success The financial landscape is changing, and Dunbridge Financial is leading the way. As a valued partner, you'll play a crucial role in shaping the future of international payments, and in return, enjoy the benefits of a rewarding and lucrative partnership. How to Become a Dunbridge Financial Partner Becoming a Dunbridge Financial partner is simple. Just reach out to our team, and we'll guide you through the seamless onboarding process. Whether you're an individual entrepreneur, a business owner, or an organization looking for new opportunities, we welcome you with open arms. Embrace the Future with Dunbridge Financial Don't miss this chance to be a part of something extraordinary. Join Dunbridge Financial and become a driving force in the financial revolution. Earn commissions, disrupt the industry, and shape the future of international payments. Together, we'll achieve greatness. Take the First Step Contact us today and embark on a journey that will transform your business and shape the financial landscape for years to come. Partner with Dunbridge Financial and be a part of the future. Let's make history together. View Details

Hydraulic Set Large Bore Retrievable 7” Production Packer

HPL-1 Hydraulic Set Retrievable Production Packer – Large Bore Design for Enhanced Performance

The HPL-1 Hydraulic Set Retrievable Production Packer is a large-bore, hydrostatic-set, double-grip packer, designed to optimize production, injection, and zonal isolation applications. Its expanded internal diameter provides increased flow capacity, reducing pressure drop and improving overall well efficiency. The packer is set using tubing pressure, eliminating the need for tubing manipulation and making it particularly effective in low hydrostatic head wells where conventional setting methods may be challenging. Once engaged, the multiple packing element system ensures a mechanically locked, high-integrity seal, sustaining pack-off force throughout its operational life.

To maintain wellbore stability, the hydraulic hold-down pistons engage after setting, preventing movement due to differential pressure. The body lock ring securely traps the setting force, ensuring that bottom-hole pressure fluctuations or tubing contraction do not compromise the seal. The large bore configuration makes the HPL-1 packer especially suited for high-volume production, deviated wells, and applications requiring unrestricted flow paths for enhanced reservoir performance.

For retrieval, operators can apply a straight upward pull or utilize the optional right-hand rotational release, depending on well conditions. The shear release mechanism enables controlled removal, minimizing downtime and reducing the risk of stuck tools. With its large-bore capability, secure hydraulic setting, and reliable retrievability, the HPL-1 packer is a high-performance solution for maximizing production efficiency, minimizing flow restrictions, and optimizing well completions.

View Details

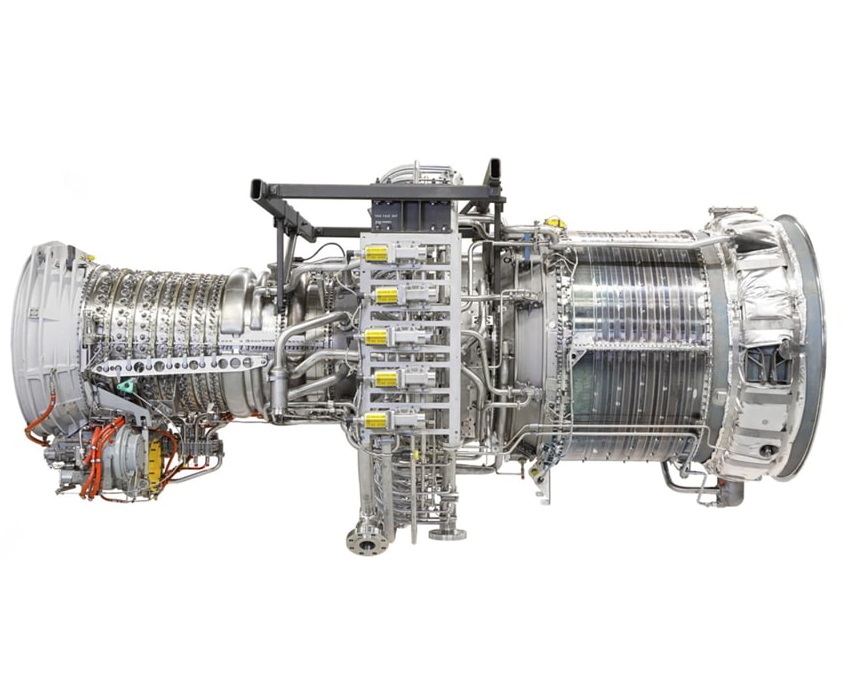

The LM2500 SAC Gas Turbine features a Single Annular Combustor (SAC) system—a type of combustion chamber where fuel and air are mixed and burned in a single, annular-shaped chamber. This design allows for efficient combustion with lower emissions and better fuel-air mixing. The turbine also supports dual-fuel capabilities, operating on both gas and diesel, offering greater flexibility in environments where fuel availability may vary.

Its open configuration is designed for accessibility, making maintenance tasks faster and more straightforward. This also allows for quicker engine removal or replacement, helping reduce downtime during service operations.

The LM2500 SAC is widely used across multiple industries, including electrical power generation, mechanical drive systems, and marine propulsion, due to its reliability, fuel flexibility, and proven performance in demanding conditions.

View Details

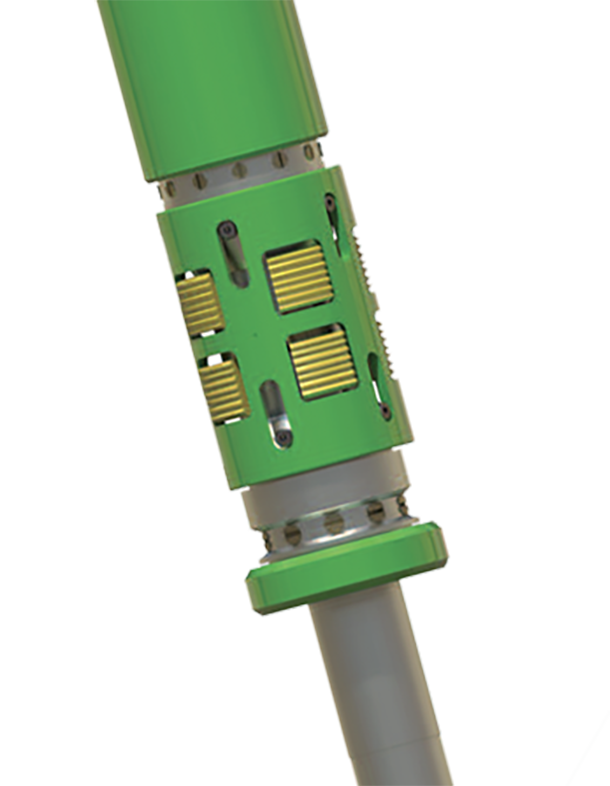

9 5/8" HP-6 Hydraulic Set High Angle Production Packer for 36-43.5 PPF Casing

Ballycatter HP-6 High Angle Production Packer

Available sizes: 4 1/2”, 5”, 5 1/2”, 6 5/8”, 7”, 7 5/8”, and 9 5/8”

The Ballycatter HP-6 is a compact, hydraulically set production packer designed for low to medium-pressure applications in high-angle and horizontal wells. With a short body length and no tubing movement required for setting, the HP-6 is ideally suited for tight-radius deviations, stacked completions, and coiled tubing operations.

It can be run in single or multiple packer installations with sequential setting in a single trip, reducing rig time and complexity.

Rated to 7,500 psi and tested in Q125 casing, the HP-6 features a straight-pull release mechanism that is fully isolated from hydraulic pressure, allowing low shear-out force even under full differential pressure.

Built-in bypass ports equalize pressure during retrieval, ensuring smooth release and reducing swab risk. The tool can be set using rig pumps, and its economical design allows for easy redress and reuse. Optional rotational release is available for added flexibility in challenging retrieval scenarios.

Engineered with materials and elastomers for hostile environments, the HP-6 delivers dependable performance in offshore operations, high-angle wells, and cost-sensitive completions requiring reliability without unnecessary complexity.

View Details

Magic Weld 150A Welding Machine and Generator

Introducing the MAGIC WELD 150: Unleash the Power of Portability and Performance! At Canaweld, we understand the challenges welders face on-site and in the field. That's why we're proud to present the MAGIC WELD 150 - the perfect fusion of welding capabilities and generator portability, designed to revolutionize your welding experience. Powerful Performance in a Lightweight Package The MAGIC WELD 150 is a true marvel in its class, offering a remarkable 150-Amp DC Stick welder with an outstanding Honda GX 200 four-stroke engine. This dynamic combination ensures a powerful and steady arc, empowering you to tackle any welding task with ease and precision. Designed for Everyday Use Built for welders who demand the best, the MAGIC WELD 150 is engineered for everyday use as a welder. Its sturdy construction and high-frequency voltage control guarantee smooth welding with all types of electrodes, including cellulosic electrodes, making it a versatile tool for various welding applications. Portability Meets Efficiency Weighing in at just 75 lbs. (34 Kg), this lightweight powerhouse is your go-to companion on-site and around the farm. The 150A in 60% duty cycle ensures consistent performance, while the auto idle feature increases fuel efficiency and extends the engine's lifespan, saving you valuable time and resources. Power Optimizer Function - Your Safety, Our Priority With safety at the forefront, the MAGIC WELD 150 is equipped with a "Power Optimizer" function, a special feature patented by MOSA. This innovative technology prevents engine overload when working near its power limit, offering you peace of mind while you work. Unmatched Certifications and Regulations Rest assured, the MAGIC WELD 150 is CE certified, meeting the highest standards of quality and safety. Its engine complies with U.S. EPA and California EXH/EVP SORE Regulations, making it an eco-friendly and responsible choice. Elevate Your Welding Experience with MAGIC WELD 150 Empower yourself with the MAGIC WELD 150 and experience the unmatched fusion of welding capabilities and generator portability. Take control of your welding tasks like never before and unleash the magic of precise and efficient welding on the go. Canaweld - Your Partner in Portability and Performance At Canaweld, we take pride in providing welding machines and accessories designed to meet the unique needs of welders in the oil and gas industry. The MAGIC WELD 150 embodies our commitment to excellence and innovation, and we are excited to offer you this game-changing welding solution. Unlock the magic of welding prowess and unparalleled portability with the MAGIC WELD 150. Your welding success awaits! Canaweld - Empowering Your Welding Journey! View Details

Surface Controlled Subsurface Safety Valve NE 2-3/8

The NE™ tubing-retrievable safety valve (TRSV) is a single rod-piston non-elastomer flapper valve designed for general production with enhanced reliability and long life. The valve includes the non-elastomer hydraulic actuator design from the highly reliable SP™ line of safety valves. Along with the metal-to-metal (MTM) body joints and closure mechanism, the actuator places this valve in the premium category while keeping costs economical. The simple, compact design enhances the valve’s overall reliability and provides for trouble-free operation. Applications » General production completions » Hostile well environments incompatible with elastomers Features » Non-elastomer dynamic piston seals » Simple compact design » 100% MTM well containment in closed position » Positive debris barrier at both ends of flow tube » No construction seals used in the lockout and communication system » Unique flow tube construction prevents debris from settling on top of flow tube *information referenced from supplier catalog. View Details

MS-201 Multistage Steam Turbine

Elevate Your Operations with the Kessels MS-201 Multistage Steam Turbine: Unmatched Power and Efficiency In the ever-evolving world of the oil and gas industry, precision and performance are paramount. At Kessels Steam Turbines, we're proud to introduce the MS-201 Multistage Steam Turbine, an engineering marvel that redefines excellence in steam turbine technology. Mastering Back-Pressure Turbines Back pressure turbines are the backbone of industrial steam applications, and our MS-201 Multistage Steam Turbine takes them to an entirely new level. Available in both single-stage and multi-stage configurations, these turbines serve as the critical link between boiler units and process steam headers, revolutionizing steam utilization and electricity generation. Efficiency That Sets a New Standard At the heart of the MS-201 Multistage Steam Turbine lies the essence of back pressure turbines – the straight-back pressure design. This innovation ensures the seamless utilization of exhaust steam, aligning precisely with process demands. Every unit of electrical power generated is consumed as per the process steam demand, marking a new pinnacle of efficiency. Applications Without Boundaries Our MS-201 turbine is not just a machine; it's a versatile powerhouse ready to excel in diverse applications: Drive Applications: Whether in the oil and gas sector, sugar mills, sugar fibrizor systems, shredder drives, pump drives, or beyond, our turbine delivers power where it's needed most. Power Generation Applications: Embrace sustainability by using our turbine to generate electricity, powering generators with clean and efficient steam energy while reducing your carbon footprint. Bleed Back-Pressure Steam Turbines Kessels understands that adaptability is key. Our MS-201 turbine features built-in bleed points, enabling uncontrolled extraction of steam within a medium pressure range. This feature proves invaluable when low-volume steam demands and high tolerance for pressure variations are critical. Kessels turbines seamlessly combine the best of both bleed and back-pressure mechanisms. Extraction Back-Pressure Steam Turbines For industries with substantial process steam demand volumes and zero tolerance for pressure variations, our steam turbines with controlled extraction vents shine. Operating efficiently under intermediate pressure levels, these turbines ensure a consistent and reliable steam supply on which your operations can depend. Why Choose Kessels? Choosing Kessels Steam Turbines is more than a business decision; it's a commitment to a legacy of excellence, innovation, and reliability. Our MS-201 Multistage Steam Turbine is the embodiment of these principles, offering you: Unmatched Efficiency: Maximize steam utilization while minimizing waste, resulting in substantial cost savings and increased productivity. Reliability Beyond Question: Built with precision and rigorously tested to ensure uninterrupted operations, even in the harshest industrial environments. Unparalleled Versatility: Adapt effortlessly to changing needs, whether for drive applications or eco-friendly power generation, with the confidence that Kessels has you covered. A Sustainable Tomorrow: Harness the power of steam for electricity generation, reduce your environmental impact, and contribute to a greener future. Expert Support: Our team of specialists is at your service, ready to assist with installation, maintenance, and troubleshooting. Empower Your Future with Kessels In the fiercely competitive world of the oil and gas industry, every advantage counts. Step into a future of efficiency, reliability, and sustainability with the Kessels MS-201 Multistage Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you toward unprecedented success. Kessels Steam Turbines – Powering Progress, Powering You. View Details

MC Injection Safety Valve 3-1/2 inch

MC (flapper-type) injection valves are used in injection wells to automatically shut-in the tubing string when injection stops or flow reverses. MC injection valves are spring-loaded, wireline-retrievable valves with large bores. The MC injection valves also feature sealing areas that are out of the direct flow path. These valves are designed to be held open by injection pressure for fluid passage. If injection flow becomes static or reverses for any reason, the spring and/or reverse flow causes the valves to close. These valves are designed to remain closed until pressure differential across the valves is equalized and injection is resumed. Applications » Injection wells Features » MC valves have sealing areas that are out of the direct flow path *information sourced from manufacturer View Details

Receive Foreign Payments with Ease

Unlock Faster Payment Solutions with Dunbridge Financial: Receive Foreign Payments with Ease Are you tired of waiting for foreign payments to arrive and tired of dealing with complex international transactions? At Dunbridge Financial, we understand the frustration that comes with delayed payments from foreign companies. Our financial service is here to revolutionize the way you receive foreign payments, ensuring you get paid faster and without the hassle. Receive Foreign Payments with Ease With Dunbridge Financial, you can now say goodbye to lengthy delays and welcome faster payment solutions. We have designed our platform to make receiving foreign payments a breeze, so you can focus on growing your business without worrying about late payments. Why Choose Dunbridge Financial? 1. Streamlined Payment Processes Our platform streamlines the entire payment process, making it quick and efficient. No more dealing with complicated paperwork or slow banking systems. With Dunbridge Financial, you'll experience a seamless and hassle-free way to receive foreign payments. 2. Speed Up Your Cash Flow Getting paid faster means improving your cash flow and having more flexibility in managing your business finances. With Dunbridge Financial's fast payment solutions, you can put your money to work sooner, helping your business thrive. 3. Secure and Reliable Your financial security is our top priority. We partner with trusted payment service providers who adhere to strict security standards, ensuring that your funds and data are safe and protected at all times. 4. Expert Customer Support We are more than just a financial service provider; we are your dedicated partner in your financial journey. Our experienced team of customer support professionals is here to assist you every step of the way, providing expert guidance and personalized solutions. Join Us Today and Unlock Faster Payment Solutions Don't let delayed foreign payments hold you back. Join Dunbridge Financial today and experience a world of faster payment solutions and enhanced financial control. With our streamlined processes, secure platform, and dedicated customer support, you'll never have to worry about slow payments again. Empower your business with Dunbridge Financial. Sign up now and embrace a new era of financial efficiency and success. Receive foreign payments with ease and enjoy the benefits of faster cash flow, giving your business the edge it deserves. View Details

Circulating Type Blanking Plugs for Nipples

HOCA Oil Tools: Enhancing Well Integrity with Circulating Type Blanking Plugs for Nipples In the intricate world of oil and gas extraction, maintaining well integrity while ensuring operational efficiency is paramount. HOCA Oil Tools, a leader in providing innovative downhole slick line tools, introduces its Circulating Type Blanking Plugs for Nipples, designed to meet and exceed these essential industry requirements. Tailored for seamless integration with landing nipples in wellbores, our products stand as a testament to our commitment to quality, efficiency, and safety in downhole operations. HOCA's Circulating Type Blanking Plugs for Nipples: Engineered for Superior Performance Our Circulating Type Blanking Plugs are meticulously designed to offer robust sealing and pressure control capabilities within the wellbore. These tools are essential for operators looking to manage fluid movement, conduct pressure tests, and maintain well integrity during various stages of well operations. Constructed from high-grade materials and engineered to meet the rigors of the downhole environment, our blanking plugs ensure reliability, durability, and performance. Experience the HOCA Oil Tools Advantage Opting for HOCA Oil Tools’ Circulating Type Blanking Plugs for Nipples means selecting a solution that embodies innovation, operational excellence, and reliability. Our commitment to delivering high-quality downhole solutions ensures that our products not only meet but surpass the challenges faced in modern oilfield environments. By incorporating our Circulating Type Blanking Plugs into your downhole operations, you take a step towards enhanced well integrity, safety, and operational efficiency. With HOCA Oil Tools, you gain not just a supplier but a partner dedicated to supporting your downhole challenges with state-of-the-art solutions and comprehensive service. Choose HOCA Oil Tools for your downhole needs and unlock the full potential of your operations with our Circulating Type Blanking Plugs for Nipples. Partner with us, and elevate your downhole operations to new levels of success and efficiency. With HOCA Oil Tools, enhance your downhole activities with tools that set new industry standards for reliability, safety, and performance in the competitive world of oil and gas extraction. View Details

Custom Application Development Services

Unleash Innovation and Elevate Your Business with ELEKS' Custom Application Development Services In today's dynamic business landscape, having a cutting-edge software solution that caters to your unique needs is no longer a luxury – it's a strategic necessity. ELEKS, a leader in the software engineering industry, offers a comprehensive suite of custom application development services that empower you to bring your boldest software visions to life. Our end-to-end approach ensures that your business stays ahead of the curve, delivering an exceptional user experience that sets you apart from the competition. Transforming Visions into Reality: How We Can Help You At ELEKS, we understand that every software vision is unique. Our custom application development service is designed to assist you in every step of your journey, from idea inception to implementation. Here's how we'll make a difference for you: 1. Validating Your Vision We kick-start your application development process with product design workshops that help shape your concepts and validate your ideas through data-led product design. Our Proof of Concept (PoC) development enables you to explore and invest in ideas that hold real business value, ensuring that your efforts are directed towards solutions with a high potential for success. 2. Innovating and Competing Innovation is at the heart of what we do. Our dedicated Research and Development (R&D) team is adept at crafting strategic solutions for even the most complex custom application development projects. Leveraging innovative technologies, we ensure that your products are tailor-made for rapidly evolving markets, giving you a competitive edge. 3. Maximizing Efficiency Automation is the key to releasing resources for delivering superior service. Once we've defined your application development requirements, we take full responsibility for the delivery team and project implementation. This allows you to concentrate on your core business activities while we handle the technical intricacies. 4. Accelerating Delivery Meeting demanding deadlines is crucial. Our nearshore team of software experts is here to assist you in cost-effectively achieving your goals, surpassing what in-house development alone can offer. With decades of experience and a proven delivery framework, we ensure consistency and minimize bottlenecks, enabling faster project delivery. 5. Ensuring Future-Proofing Future-proofing is paramount in the tech world. We establish a continuous integration/delivery process that lets you seamlessly check and deliver code changes across multiple platforms. This approach not only enhances your software ecosystem but also allows you to provide an exceptional service to your customers. 6. Ensuring Operational Resilience and Agility Incorporating Cloud, AI, and RPA technologies, we help you build digitally resilient ecosystems. These ecosystems allow you to adapt swiftly to market changes, fostering business growth. Our rigorous business analysis ensures a tailored, cost-effective technology solution that supports your business needs and continuity plans. Unveiling Our Services: Transforming Concepts into Reality ELEKS offers a range of comprehensive application development services to cater to all your needs: Desktop Software Our full-cycle application development includes seamless desktop app integration for various operating systems, ensuring a smooth experience for users of Windows, macOS, and Linux. Web Applications From technology consulting and UX design to front and back-end development, deployment, and support, our web application development service covers every aspect of creating successful web solutions. Custom Mobile Apps Our mobile application development services provide end-to-end solutions for iOS and Android platforms, delivering flawless performance, robust security, and an enhanced user experience. Data Warehouse and BI Solutions We specialize in delivering advanced Data Warehouse and Business Intelligence solutions across different domains, unlocking actionable insights and driving operational efficiency. Our Workflow: Making Your Vision a Reality Our application development process involves key steps that ensure the success of your project: 1. Idea Validation: We collaborate with you to outline your requirements, identifying ideas that hold the most potential for long-term success. 2. Innovation and Development: Our expert development team designs a custom solution utilizing emerging technologies to address gaps in your current IT ecosystem. 3. Software Testing: We ensure your custom app meets both functional requirements and quality standards, performing user acceptance testing and providing support with technical documentation. 4. Project Governance: Our governance covers product deployment, progress reporting, and issue resolution, keeping you informed and your project on track. When you partner with ELEKS, you're partnering with a Top 100 Global Outsourcing development company that places your project in capable hands. Unlock Your Potential with ELEKS ELEKS' custom application development services are more than just solutions – they are opportunities to innovate, compete, and thrive in the digital age. With a dedicated team of over 2000 software experts and a proven track record of success, we're ready to transform your ideas into reality. Contact us today to embark on a journey of innovation, efficiency, and growth with ELEKS as your trusted partner. View Details

WellStar Tubing Retrievable Surface Controlled Subsurface Safety Valve 2-7/8 inch Halliburton

The WellStar® tubing-retrievable safety valve (TRSV) is a general production, hydraulically operated, downhole TRSV. The rugged hydraulic actuator of the WellStar safety valve provides durability and isolates the internal workings from well fluids through its unique construction. The metal-to-metal (MTM) sealing integrity in the body joints and closure mechanism places it in a premium valve category while featuring an economical price. Proven through years of installations, the simple, compact design enhances the valve’s overall reliability and provides for trouble-free operation. Applications » General production completions Features » Simple, compact design » Complete MTM well containment in the closed position (body/seat connections and flapper) » MTM flapper sealing (no resilient seal required) » Unique hydraulic actuation (single-piece piston/ flow tube) » Hydraulic chamber construction isolates the majority of the internal valve components and exposes them to clean hydraulic fluid » Positive debris barrier at both ends of flow tube in full open position » Maximized piston area and spring force » Flow tube construction prevents well solids and debris from settling on top of the piston *information referenced from supplier catalog. View Details

Tubing Hanger Coupling - 4 ½” to 2 3/8”

The 4 ½” x 2 3/8” tubing hanger coupling is a specialized downhole component designed to connect two different sizes of upset tubing within a wellhead assembly. Upset tubing refers to tubing that has thicker, reinforced sections at the ends—called “upsets”—which strengthen the threaded connections and help withstand the mechanical stresses and high pressures encountered during well operations. This coupling provides a secure and pressure-tight transition between a larger 4 ½-inch tubing hanger and a smaller 2 3/8-inch production tubing string, enabling effective management of wellbore fluids and maintaining pressure containment.

Engineered to integrate seamlessly with tubing hanger spools, wrap-around tubing hangers (PTHSW), and ‘PTHS’-type tubing spools, this coupling forms part of a modular wellhead completion system. Its union nut design allows installation by screwing the coupling in place without rotating the Christmas tree, simplifying assembly and reducing the risk of damage during installation.

Both the top and bottom ends of the coupling are threaded to customer specifications, offering flexibility for various well configurations and allowing the installation of back pressure valves to maintain well control during operations. Manufactured to API standards and constructed from high-grade materials, the coupling delivers durability and reliable performance in demanding downhole environments characterized by high pressure, temperature, and corrosive fluids.

By facilitating a smooth and strong size transition between different tubing strings, the 4 ½” x 2 3/8” tubing hanger coupling supports well integrity, operational efficiency, and safety throughout oil and gas production.

View Details

The LM2500 is a multi-shaft gas turbine featuring a free-spinning power turbine, making it well-suited for dynamic and high-demand environments such as those found in oil and gas operations. In this design, the high-pressure turbine and compressor are mechanically independent from the low-pressure power turbine. This separation allows the power turbine, which drives the electric generator or mechanical load, to respond rapidly to changes in load demand. Its ability to accelerate quickly makes it ideal for applications where maintaining grid stability or mechanical output is critical. In scenarios where frequency fluctuations occur, the free power turbine can quickly compensate, helping to stabilize the grid and ensure smoother operation of all connected systems.

In its standard configuration, the LM2500 is equipped with a six-stage, low-speed power turbine. This turbine operates at a nominal speed of 3600 rpm and is designed to deliver reliable shaft power in steady-state conditions, making it particularly effective for electric power generation or mechanical drive in pipeline and process operations.

For applications requiring greater flexibility or higher continuous output speeds, the LM2500+G4 variant offers enhanced capabilities. It is available with either the standard six-stage, low-speed power turbine or an alternative two-stage high-speed power turbine. The high-speed variant is engineered for mechanical drive and other demanding industrial uses, with a design speed of 6100 rpm and an operating range from 3050 to 6400 rpm. This configuration supports continuous high-speed shaft output where needed and is particularly beneficial for compressors and other rotating equipment in oil and gas facilities.

Both the six-stage and two-stage power turbines can be operated over a cubic load curve, providing the adaptability required for variable load profiles commonly encountered in oil and gas operations. This flexibility, combined with the LM2500’s rapid response characteristics and modular design, makes it a dependable choice for critical infrastructure in upstream, midstream, and downstream sectors.

View Details

General Mechanical Slickline Service

InWaTec Combined: Precision at Depth with General Mechanical Slickline Services In the demanding arena of oil and gas well maintenance, precision is not just a virtue—it's a necessity. At InWaTec Combined, we provide General Mechanical Slickline services that bring precision to the heart of your well operations. Our slickline services deliver targeted maintenance solutions, assuring that performance, integrity, and productivity remain at the forefront of your downhole activities. The Role of Slickline in Downhole Maintenance Slickline is the unsung hero of well servicing, a slender thread of robustness, lowering essential tools into the depths of oil and gas wells to execute critical maintenance tasks. It is the conduit for precision, the means by which tools are delivered to the precise downhole location where they are needed. Why Choose InWaTec Combined's Slickline Services? Expertise at Every Turn: Our slickline operators are seasoned experts, with the skill to navigate complex downhole environments, ensuring that every tool is deployed with accuracy. Versatile Tool Deployment: From routine maintenance to emergency interventions, our slickline services cater to a diverse range of downhole needs, delivering the right tool to the right place at the right time. Streamlined Operations: Efficiency is key in downhole operations, and our slickline services are designed to minimize downtime, streamline processes, and maintain the peak performance of your wells. Safety and Precision Combined: At InWaTec Combined, we balance the need for operational precision with an uncompromising commitment to safety, ensuring that every slickline operation upholds the highest standards. Tailored Solutions for Downhole Challenges Every well presents its own set of challenges, and InWaTec Combined's General Mechanical Slickline services are crafted to meet them head-on. We provide tailored solutions, customizing our approach to fit the unique needs of your well, ensuring that maintenance tasks are carried out with precision and care. Advanced Technology for Optimal Results We leverage the latest in slickline technology, utilizing advanced materials and innovative techniques to enhance the reliability and effectiveness of our services. Our commitment to technological advancement means that we're always at the cutting edge, providing services that are not just current but future-ready. Your Partner in Well Maintenance Choosing InWaTec Combined for your slickline needs means selecting a partner dedicated to the success of your well operations. Our General Mechanical Slickline services are a reflection of our promise to deliver excellence in every aspect of our work, from the initial deployment of tools to the completion of maintenance tasks. Conclusion: Your Well's Performance, Our Commitment In conclusion, InWaTec Combined's General Mechanical Slickline services are essential for maintaining the high performance and integrity of your oil and gas wells. With our focus on precision, efficiency, and safety, we ensure that your maintenance operations are performed to the highest standards. Trust in the expertise and dedication of InWaTec Combined to keep your wells operating smoothly, safely, and efficiently. View Details

TIG Torch 200 AMP Gas Valve Air Cooled (26 series)

Unleash Precision Welding with Canaweld's TIG Torch 200 AMP Gas Valve Air Cooled (26 Series)! For the oil and gas industry, precision welding is not just a requirement; it's an art. At Canaweld, we understand the critical role that welding plays in your projects, and that's why we offer the highest quality welding accessories to empower you with exceptional performance. Our TIG Torch 200 AMP Gas Valve Air Cooled (26 Series) is a testament to our commitment to excellence and innovation. Unmatched Flexibility: When it comes to hard-to-reach applications, our TIG Torch 200 AMP is the ultimate solution. The torch body can be bent to virtually any position, ensuring quick and easy access to even the most difficult positional welds. No more struggling with tight spaces; our torch provides unmatched flexibility, making precision welding a breeze. Revolutionary Cooling Technology: We've harnessed the power of Force Cooling Technology to maximize the performance and longevity of our torch. Highly effective passages and wells force cool the collet, resulting in a cooler running torch with increased conductivity and extended consumable life. Weld with confidence, knowing that our torch can handle even the most demanding applications. Heat Zone Isolation for Superior Performance: Our torch employs Heat Zone Isolation Technology, where transferred heat is isolated by a unique external barrier. Conducted heat is further isolated using large air pockets within the torch body structure. The result? Cooler running torches with increased power to weight performance ratios. Experience welding at elevated power levels without compromising performance. Superior Wear Parts for Increased Arc Time: Every component of our torch is designed for superior performance, delivering increased arc time and lower overall production costs. From push-on/easy grip ceramics to one-piece collet/collet body for hassle-free use, our torch ensures 100% ceramic and electrode alignment with the Heat Zone Isolator. Optional large gas lens increases the gas envelope for even more efficiency. Advanced Torch Bodies and Back Caps: Experience a step-change in performance levels with our torch bodies and back caps. Our revolutionary cooling and heat zone isolation techniques result in cooler running torch bodies at elevated power levels. These cooler running components increase wear parts' life expectancy, giving you an edge in productivity. Key Benefits for Enhanced Performance: • Utilizes air gap technology for cooler running handles • Hard and soft material elements for an effortless grip • Infinite adjustment of welding parameters from the torch handle • Optional integrated handle readout displays all welding and machine parameters in "real-time" Clever Cable Systems for Optimal Efficiency: Our cable systems are cleverly designed to combine flexibility, durability, and top-notch performance. Rapid fit and modular rear-end systems ensure easy reconfiguration of power input, gas hose, and control lead terminations. Superior-grade rubbers guarantee cable termination integrity and hose package longevity, tested to withstand over 1 million flexes. Elevate Your Welding Experience: Experience the difference with Canaweld's TIG Torch 200 AMP Gas Valve Air Cooled (26 Series). Achieve precision welding with ease, no matter how challenging the application. Trust in Canaweld's expertise and dedication to deliver premium welding accessories that redefine excellence in the industry. Your welding projects deserve nothing but the best, and that's precisely what Canaweld delivers. When it comes to welding, choose Canaweld for the ultimate in quality, flexibility, and performance. Elevate your welding experience and take your oil and gas projects to new heights of success with Canaweld's cutting-edge welding accessories. View Details

Water Injection Safety Valve Type MC 5-1/2 inch

MC (flapper-type) injection valves are used in injection wells to automatically shut-in the tubing string when injection stops or flow reverses. MC injection valves are spring-loaded, wireline-retrievable valves with large bores. The MC injection valves also feature sealing areas that are out of the direct flow path. These valves are designed to be held open by injection pressure for fluid passage. If injection flow becomes static or reverses for any reason, the spring and/or reverse flow causes the valves to close. These valves are designed to remain closed until pressure differential across the valves is equalized and injection is resumed. Applications » Injection wells Features » MC valves have sealing areas that are out of the direct flow path *information sourced from manufacturer View Details

HDI Gauge Batteries, Parts, and Repair Kits

At Houston Digital Instruments (HDI Gauges), we prioritize providing our customers with cost-effective solutions that maximize the lifespan and performance of our products. We understand the importance of minimizing downtime and inventory costs while ensuring optimal functionality. That's why we offer a range of options for maintenance and repair, including spare parts, batteries, and repair kits. Additionally, our certified repair and calibration services guarantee the highest level of quality and precision. Let's explore how HDI Batteries, Parts, and Repair Kits can enhance your operational efficiency. Field Repairability: Minimize Lifecycle Costs HDI products are designed with field repairability in mind, significantly reducing the lifecycle costs associated with using our instruments. We believe in empowering our customers to perform maintenance and repairs on their own, enabling them to minimize downtime and spare unit inventory costs. Our DIY maintenance options are user-friendly and straightforward, ensuring that you can quickly resolve issues and keep your operations running smoothly. Spare Parts and Batteries: Keep Your Instruments Performing Optimally To support your maintenance efforts, HDI offers a comprehensive range of spare parts and batteries for our products. Whether you need replacement components, sensors, connectors, or other essential parts, our inventory has you covered. By utilizing genuine HDI spare parts, you can maintain the integrity and performance of your instruments, ensuring accurate and reliable measurements in the field. Furthermore, HDI batteries are specifically designed to deliver long-lasting power and reliability. We understand the critical nature of uninterrupted operation, and our batteries are engineered to provide optimal performance, even in demanding environments. With HDI batteries, you can trust that your instruments will continue to perform at their best, enhancing your productivity and efficiency. Repair Kits: Convenient Solutions for Maintenance and Repairs HDI Repair Kits are carefully curated packages that include all the necessary components and tools to perform maintenance and repairs on your HDI instruments. These kits are designed to simplify the process, providing you with a convenient solution to address common issues quickly. With HDI Repair Kits, you can efficiently resolve minor problems, minimize downtime, and restore your instruments to peak performance. Certified Repair and Calibration: Uncompromising Quality and Precision For more complex repairs or calibration needs, HDI offers certified repair and calibration services. If you prefer to have our expert technicians handle the maintenance and calibration of your instruments, simply ship them back to HDI. Our skilled professionals will carefully assess, repair, and calibrate your instruments, ensuring they meet our stringent quality standards. With HDI certified repair and calibration, you can have complete confidence in the accuracy and reliability of your instruments. HDI Batteries, Parts, and Repair Kits provide you with comprehensive solutions to enhance the lifespan and performance of your HDI instruments. Our commitment to field repairability allows you to minimize lifecycle costs, reduce downtime, and optimize inventory management. By utilizing genuine HDI spare parts, reliable batteries, and convenient repair kits, you can keep your instruments performing at their best. Additionally, our certified repair and calibration services ensure uncompromising quality and precision. Trust HDI Gauges for all your maintenance and repair needs, and experience the benefits of our cost-effective solutions. Contact HDI today to explore our range of batteries, parts, and repair kits tailored to meet your specific requirements. View Details

LM2500 Wrench for HPT Coupling Nut

The LM2500 Wrench – Horizontal/Vertical HPT Coupling Nut is a specialized maintenance tool designed for the LM2500 gas turbine engine. This wrench is used to install and remove the High Pressure Turbine (HPT) coupling nut, a critical component that secures the HPT rotor to the turbine shaft.

Removing and installing the coupling nut is necessary during major maintenance activities like rotor inspections, repairs, or when replacing key turbine components. Proper removal allows technicians to safely separate the rotor from the shaft, while correct installation ensures the rotor is securely fastened for reliable engine operation.

What makes this wrench stand out is its ability to work with both horizontal and vertical engine positions. This means technicians can use it easily no matter how the engine is set up, making maintenance simpler and more flexible.

Built to precise standards and made from tough materials, the wrench ensures the right amount of force is applied when tightening or loosening the coupling nut. This careful control helps protect the engine’s important parts from damage.

By using this wrench, maintenance teams can complete their work faster and with confidence, reducing downtime and keeping the turbine reliable. It’s an essential tool that supports the smooth operation of the LM2500 engine.

View Details

Thru-Tubing MatrixStixx 2.25 inch

Introducing Thru-Tubing Acid Stimulation by StimStixx Technologies - Revolutionize Your Operations! Are you looking for a quick, efficient, and environmentally friendly acid stimulation solution? Look no further! StimStixx Technologies is proud to present our cutting-edge Thru-Tubing Acid Stimulation system, designed to meet all your needs with ease and precision. Our innovative product offers a hassle-free deployment process via electric wireline, ensuring a seamless integration into your operations. Available in both HCL and HCL/HF acid blends, our solution guarantees the utmost effectiveness in achieving your desired results. At the heart of our Thru-Tubing Acid Stimulation system lies a specially formulated solid acid stick. Whether you're using slickline, wireline, coil tubing, or tractor-conveyed methods, our solid acid stick delivers heated acid vapor with pinpoint accuracy directly to the zone of interest. This groundbreaking approach ensures increased penetration and contact with the formation, thanks to the highly reactive nature of the heated acid vapor. Not only does our system deliver exceptional performance, but it also provides numerous benefits that will enhance your operations in more ways than one. By utilizing our Thru-Tubing Acid Stimulation, you'll experience reduced CO2 emissions, lower downtime, and simplified implementation. The increased precision and fast-acting nature of our solution will save you valuable time and resources, while also reducing manpower, rig, and equipment costs. Additionally, the elimination of contaminated effluent means a reduced risk of spills at the surface and eliminates the need for post-treatment clean-up or disposal. Join the countless businesses already benefiting from our Thru-Tubing Acid Stimulation system. Embrace efficiency, precision, and environmental responsibility with StimStixx Technologies. Contact us today to revolutionize your operations and unlock a new level of success! View Details

WI Water Injection Valve 1.75 inch

The WI retrievable injection valve is a high-performance, high-flow rate injection valve. High throughput is achieved by a unique valve configuration that minimizes turbulent and potentially erosive flow. Operation is not dependent on a specific flow rate, pressure, or setting depth, thus negating the need for adjustment over time. The valve incorporates a metal-to-metal valve and seat energized by the combination of an integral spring and well pressure acting from below. The WI injection valve can be deployed on a wireline lock or through-tubing pack-off device, providing flexibility not available with alternative injection valve systems. As a result of the simple design with fewer parts, redress and repair costs are considerably lower than those for other injection valve systems. Applications The WI injection valve is primarily used in water injection applications as an alternative to conventional tubing or wireline-set safety valves. The valve is also commonly used as a retrofit solution in water injectors in which a tubing to annulus leak has occurred. The valve can be deployed below the leak point to eliminate uncontrolled annulus pressure increases when the injection stops. Features » Compatible with all known lock systems » Dedicated designs to suit Halliburton EB0 intervention packers » Enhanced internal flow profile » Simple design and construction » Flow-loop testing performed to establish pressure drop versus pump rate *information referenced from supplier catalog. View Details

Tubing Cutter / Drill Pipe Cutter

Introducing Tubing Cutter / Drill Pipe Cutters from ID Oiltools - the perfect solution to quickly and effectively sever tubing during the removal of stuck pipe. Our Tubing Cutters are designed to handle the toughest situations when tubing becomes stuck in the well. To achieve maximum performance, we recommend choosing the cutter with the largest possible diameter that can run in the well. Our Tubing Cutter / Drill Pipe Cutters are air shippable at Class 1.4D and conform to API RP-67, ensuring that you receive a reliable and safe product. To maximize the effectiveness of the tool, our cutters should be centralized and run in recommended applications. Don't let stuck tubing slow down your operations - trust ID Oiltools Tubing Cutter / Drill Pipe Cutters to provide a quick and efficient solution. Contact us today to learn more about how we can help you overcome the toughest challenges in your well operations. View Details

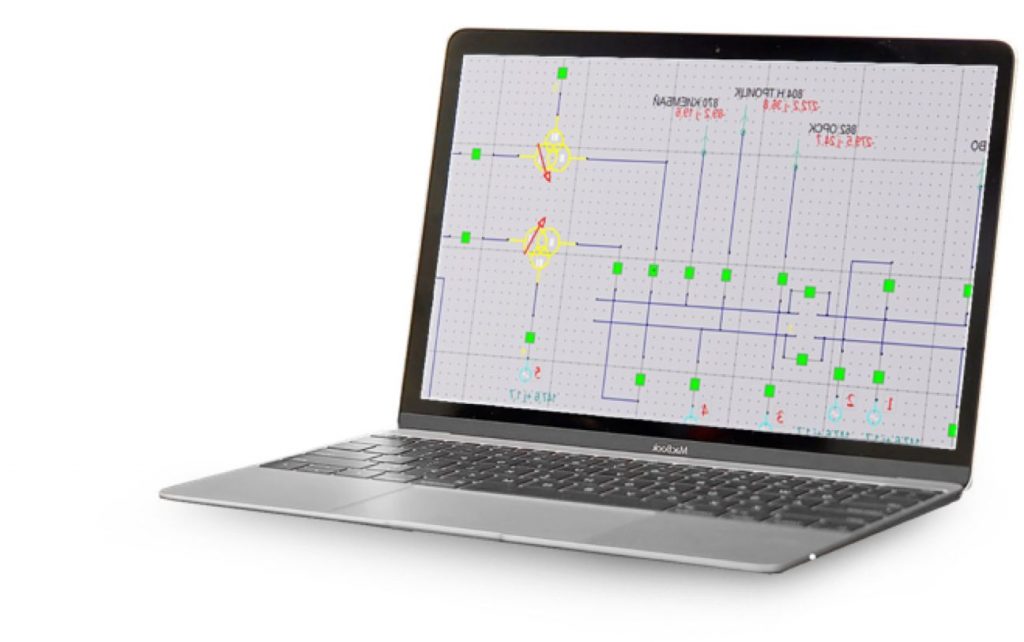

DAKAR power systems management

Elevate Power Management with DAKAR: The Future of Energy Efficiency At ELEKS, we're committed to revolutionizing the energy industry with innovative software solutions that empower businesses to thrive in the digital age. Introducing DAKAR, our cutting-edge power management system designed to enhance operational efficiency, minimize errors, and transform the way energy is managed. DAKAR has become the preferred choice for numerous European energy producers, distributors, utilities providers, design organizations, and educational institutions, and for good reason. Unleash the Power of DAKAR Seamless Integration: DAKAR seamlessly integrates into any power industry organization, ensuring a smooth transition to advanced power management solutions without disrupting your existing workflows. Comprehensive Capabilities: Experience extensive capabilities for utilities network management, modeling, and planning. DAKAR empowers you to optimize your power networks, ensuring they operate at peak efficiency while adapting to both traditional and renewable energy sources. Enhanced Accuracy and Reliability: With DAKAR by your side, you can elevate the accuracy and reliability of your power systems. Our software empowers you to make informed decisions based on real-time data, leading to reduced errors and improved performance. Real Results, Real Numbers Impressive Customer Base: With a track record of success, DAKAR is trusted by 250 customers across diverse industries. From energy suppliers to educational institutions, businesses worldwide rely on DAKAR for streamlined power management. Leading Ukrainian Energy Suppliers: In Ukraine, where the energy landscape is evolving rapidly, DAKAR stands out as the software of choice for 2/3 of energy suppliers. Its impact on efficiency and productivity is undeniable. 40% Productivity Growth: Businesses using DAKAR have experienced a remarkable 40% growth in productivity. This tangible result speaks volumes about the transformative power of our software in enhancing operational efficiency. ELEKS: Pioneering Energy Innovation For over three decades, ELEKS has been at the forefront of technology and innovation, creating solutions that drive industries forward. DAKAR embodies our commitment to shaping the energy industry for the better, providing unparalleled tools to manage power systems with accuracy and precision. Experience the Future of Power Management Embrace the future of power management with DAKAR by ELEKS. Join the ranks of satisfied customers who have unlocked efficiency, minimized errors, and achieved remarkable growth. Elevate your operational efficiency and take control of your energy systems like never before. With DAKAR, the future is bright, sustainable, and powered by cutting-edge technology. View Details