HDI Gauge Batteries, Parts, and Repair Kits

Gauge Parts

Also known as:

Spare Parts, Field Repair Kits, Digital Gauge Parts, Rig Gauge Parts

HDI Gauge Batteries, Parts, and Repair Kits

Gauge Parts

Also known as:

Spare Parts, Field Repair Kits, Digital Gauge Parts, Rig Gauge PartsBuy

In Stock

Manufacturer

Price:

Request for QuoteShipping:

Air freightDelivery Time:

3 WeeksNote:

Gauge Batteries, Parts, and Repair Kits are maintenance tools designed to extend instrument life, reduce downtime, and ensure reliable operation in the field.Sign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Executive Summary

HDI Gauge batteries, parts, and repair kits are important for keeping measurement instruments working properly. They are made so users can fix and maintain equipment on-site, which helps reduce downtime and lowers the need to keep many spare units in stock. Using genuine parts helps ensure the instruments stay accurate and reliable. The batteries provide long-lasting power even in tough conditions. Repair kits include all the tools and parts needed for common repairs. For more serious repairs or calibration, certified services are available to make sure the instruments meet quality standards. Together, these options help manage equipment efficiently and extend its life.

Technical Specifications

| Battery Type | 3.6 V Lithium Thionyl Chloride |

| Battery Life | Approx. 12 to 18 months continuous use |

| Replaceability | Field replaceable |

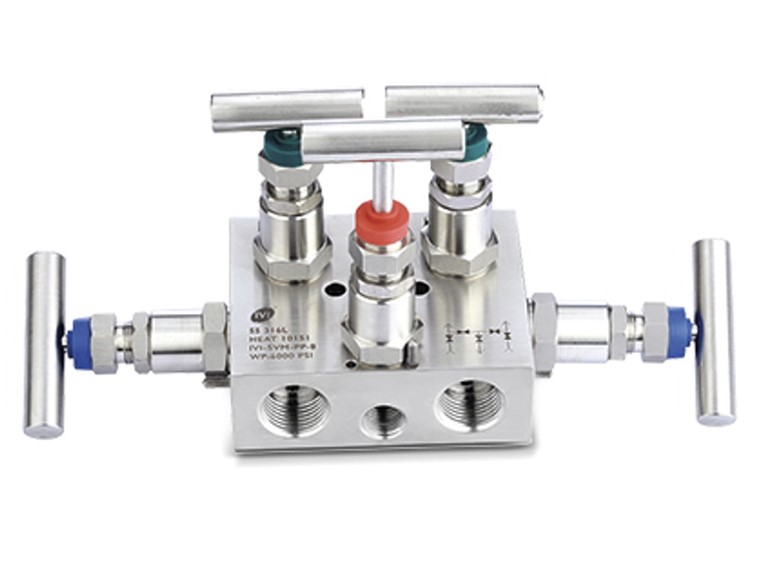

| Repair Kits Contents | Replacement seals, O-rings, connectors, screws, calibration tools |

| Compatibility | Designed for specific gauge models to ensure proper fit and function |

| Operating Temperature | Typically -40°C to +70°C (varies by part) |

| Connector Types | Standardized connectors |

| Operating Environment | Suitable for harsh conditions including vibration |

| Interchangeable Components | Key parts like displays, sensors, and processor boards are replaceable |

| Calibration Accuracy | Calibration kits maintain instrument accuracy per factory specs |

Features and Benefits

- Field Repairability: Minimize Lifecycle Costs.

- Spare Parts and Batteries: Keep Your Instruments Performing Optimally.

- Repair Kits: Convenient Solutions for Maintenance and Repairs.

- Certified Repair and Calibration: Uncompromising Quality and Precision.

- Extends equipment lifespan through targeted maintenance.

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

HDI Gauge systems used in oil and gas operations are often exposed to harsh environments and continuous use. To maintain accuracy, reduce downtime, and extend the service life of these systems, it is critical to have access to replacement components that are both durable and compatible. A full range of spare parts is available to support maintenance needs, including displays, sensors, cables, processor boards, connectors, and housing elements.

These parts are designed to be interchangeable across compatible models, allowing operators to replace worn or damaged components without requiring full system replacement. This modularity improves cost efficiency and simplifies logistics, especially in remote field locations. Most components are field-replaceable, reducing the need for specialized service technicians and enabling faster return to operation.

Processor boards and display units typically share a common design across multiple gauge models, streamlining inventory requirements and providing flexibility during urgent repairs. Sensors are matched with gauge heads for calibration accuracy but can be easily re-paired and recalibrated in the field or through service support if needed.

Using certified or manufacturer-specified replacement components ensures continued compliance with safety standards, maintains the expected measurement accuracy, and supports the longevity of the equipment. These parts are often backed by service documentation or part tracking for maintenance records and equipment history management.

In short, a well-organized supply of compatible, high-quality parts is essential for effective pressure and temperature gauge system upkeep in demanding industrial settings.