HDI 2200 Choke Position Indicator System

Choke Position Indicator

Also known as:

Linear Potentiometer, Rotary Potentiometer, Retractable Potentiometer

HDI 2200 Choke Position Indicator System

Choke Position Indicator

Also known as:

Linear Potentiometer, Rotary Potentiometer, Retractable PotentiometerBuy

In Stock

Manufacturer

Price:

Request for QuoteShipping:

Air freightDelivery Time:

3 WeeksNote:

A battery-powered electronic gauge used to monitor the position of choke valves in oil and gas operations, displaying valve position from 0% to 100% for accurate flow control.Sign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Executive Summary

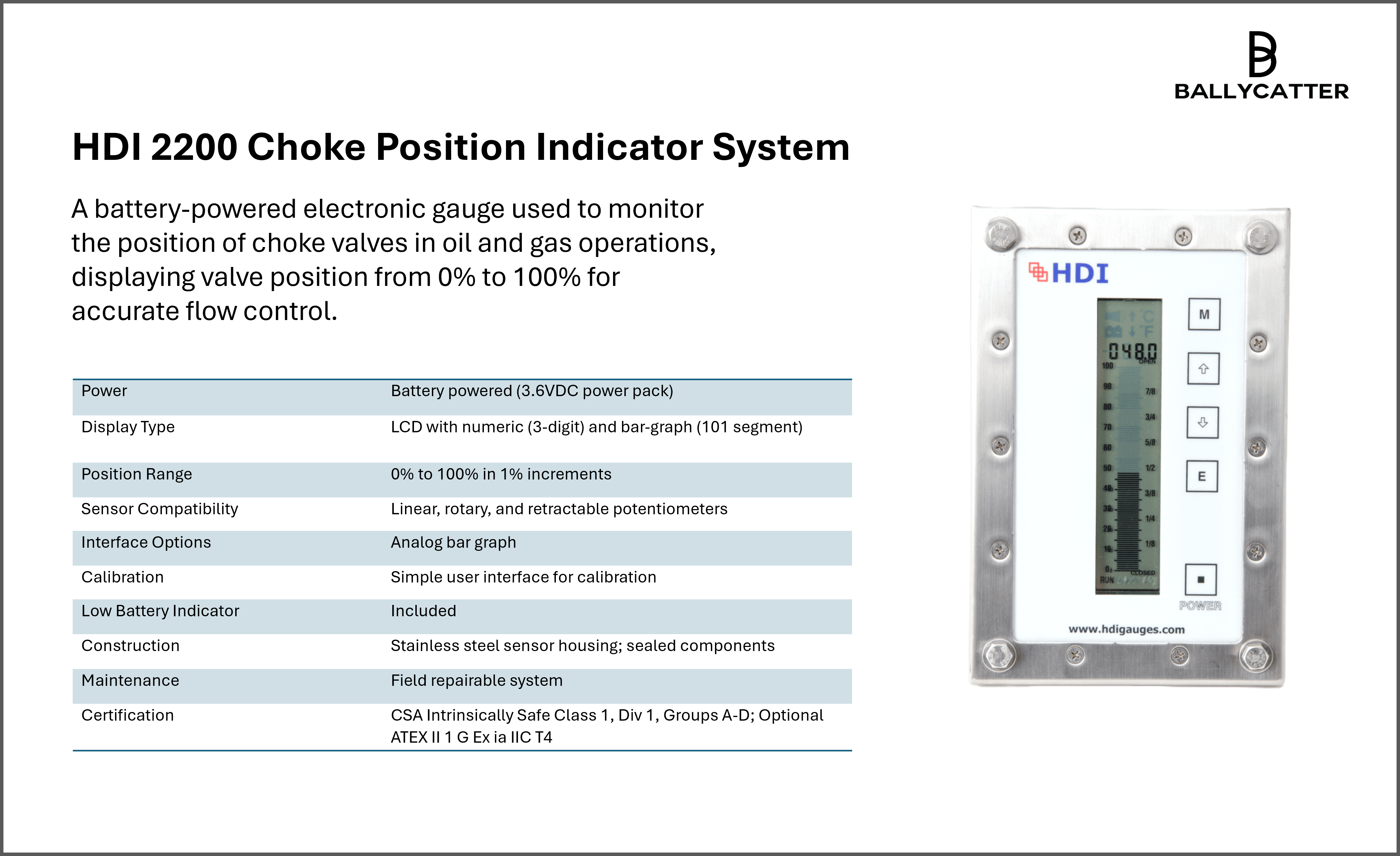

The HDI 2200 Choke Position Indicator System is a solid-state, electronic monitoring solution used to measure and display the position of choke valves in oil and gas operations. It shows valve position from 0% to 100% in 1% increments using a combination of numeric and bar-graph displays. The system connects to a range of sensor types—including linear, rotary, and retractable potentiometers—and can be adapted to fit a variety of choke brands such as Shaffer/NOV, Cameron, Swaco, and others.

Often used in dual-choke applications within choke console systems, the 2200 provides precise visual feedback for operators to monitor choke and kill lines independently. It requires no air lines, has minimal maintenance needs, and is suited for high-vibration and hazardous environments, making it a reliable, field-ready choice for real-time choke position monitoring.

Technical Specifications

| Power | Battery powered (3.6VDC power pack) |

| Display Type | LCD with numeric (3-digit) and bar-graph (101 segment) |

| Position Range | 0% to 100% in 1% increments |

| Sensor Compatibility | Linear, rotary, and retractable potentiometers |

| Interface Options | Analog bar graph |

| Calibration | Simple user interface for calibration |

| Low Battery Indicator | Included |

| Construction | Stainless steel sensor housing; sealed components |

| Maintenance | Field repairable system |

| Certification | CSA Intrinsically Safe Class 1, Div 1, Groups A-D; Optional ATEX II 1 G Ex ia IIC T4 |

Features and Benefits

- Solid-state display with numeric and bar graph.

- Accurate, real-time choke position monitoring.

- Low maintenance and reliable operation.

- Supports remote monitoring and automation.

- Dual sensor support for HMI/PLC integration.

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

The HDI 2200 Choke Position Indicator System is a battery-powered, intrinsically safe solid-state electronic gauge designed to monitor choke valve positions in oil and gas operations with high accuracy. It displays choke position in 1% increments from fully closed to fully open (0% to 100%) using a three-digit numeric readout alongside an analog bar graph segmented into 101 divisions for both precise measurement and quick visual trend analysis.

The system interfaces with linear, rotary, or retractable potentiometers housed in stainless steel enclosures. This flexibility allows for straightforward adaptation across many choke configurations without the need for onsite customization. The sealed stainless steel housing and solid-state electronics enable the 2200 to operate reliably in harsh field conditions, including high vibration environments typical in land and offshore drilling.

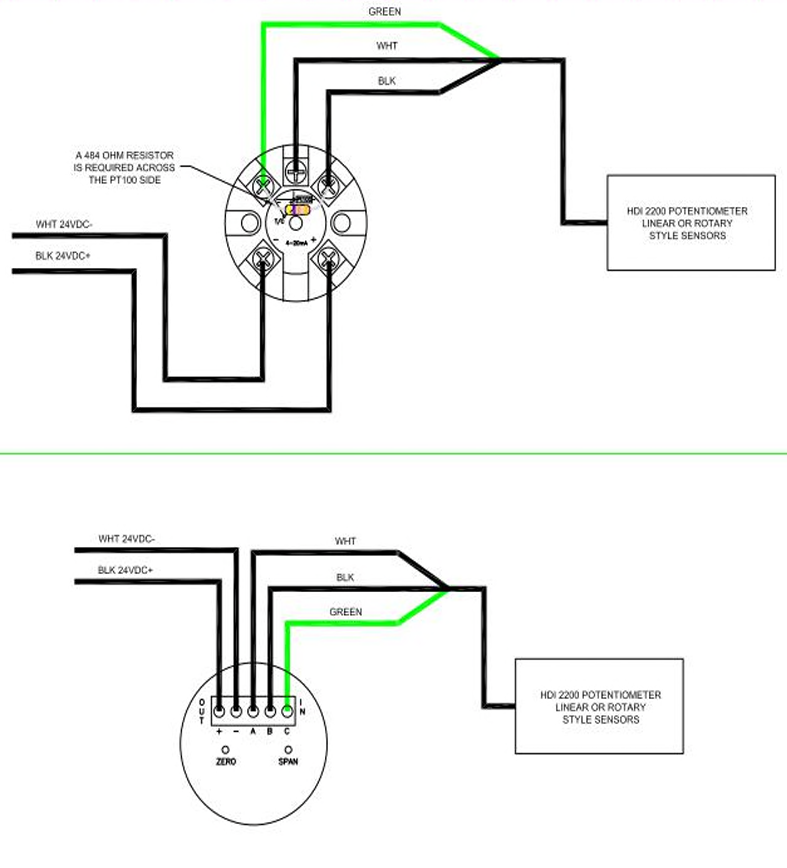

Its compact display unit measures approximately 8 by 8 by 4 inches and weighs around 5 pounds. The system is powered by an intrinsically safe 3.6V DC battery pack, with a low battery indicator to ensure timely maintenance and uninterrupted operation. Field-repairable components minimize downtime and allow for easy servicing. The system supports dual sensors for integration with human-machine interfaces (HMI) or programmable logic controllers (PLC), enabling remote monitoring and automation. The 2200 system replaces traditional pneumatic indicators, eliminating the need for air lines and reducing maintenance complexity, while offering a simple calibration interface to facilitate setup and ongoing adjustments.

Engineering Data