HDI 2100 Pump Stroke Counter System

Pump Stroke Counter

Also known as:

Solid-State Electronic Stroke Counter, Mud Pump Stroke Counter

HDI 2100 Pump Stroke Counter System

Pump Stroke Counter

Also known as:

Solid-State Electronic Stroke Counter, Mud Pump Stroke CounterBuy

In Stock

Manufacturer

Price:

Request for QuoteShipping:

Air freightDelivery Time:

3 WeeksNote:

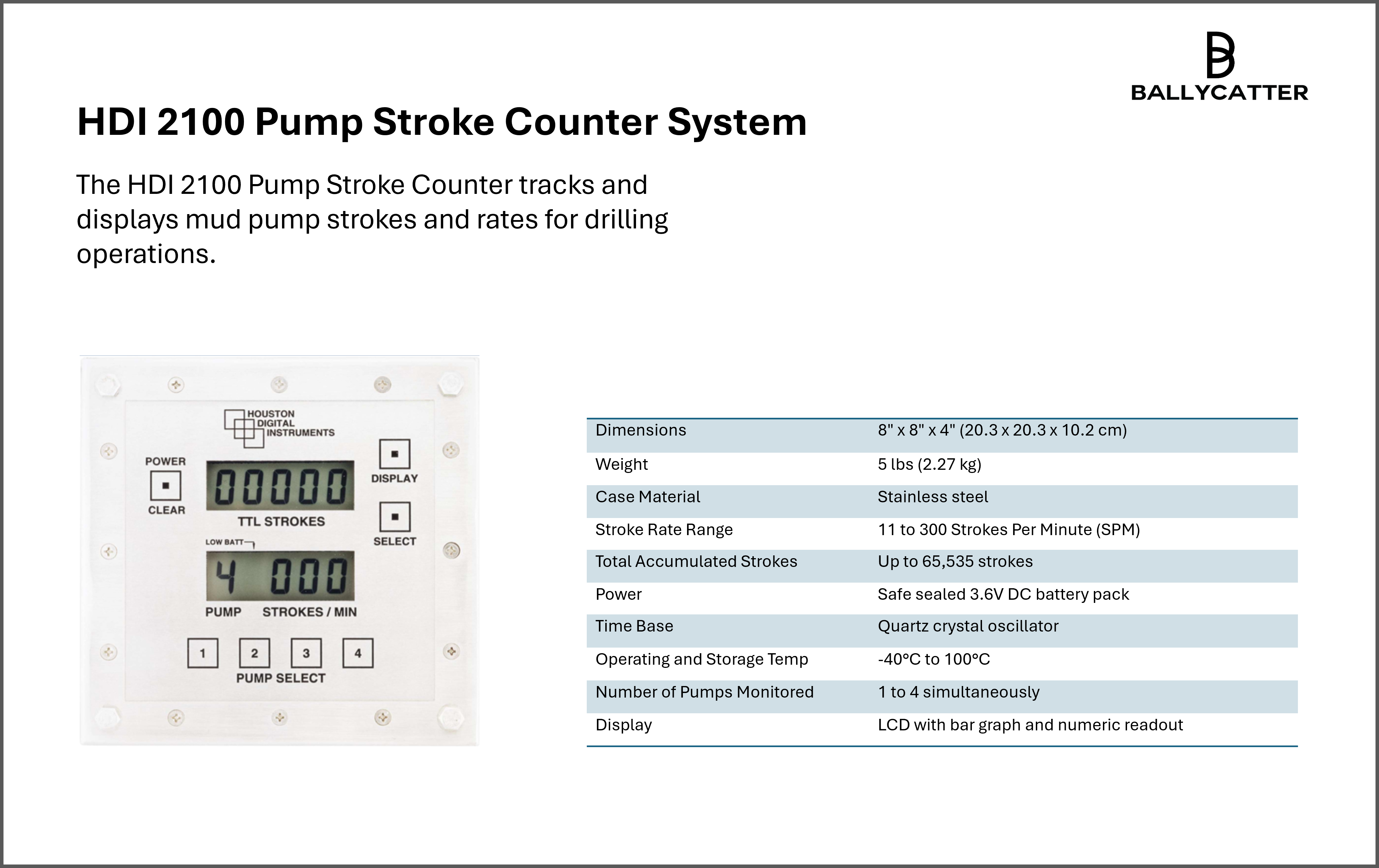

The HDI 2100 Pump Stroke Counter tracks and displays mud pump strokes and rates for drilling operations.Sign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Executive Summary

The HDI 2100 Pump Stroke Counter System is an electronic instrument that measures and displays the total strokes and stroke rate of up to four mud pumps at the same time. It provides real-time data needed to monitor pump performance during oil and gas drilling operations.

The system features a sealed stainless steel case and durable sensors to handle harsh environments. Its quartz crystal oscillator delivers precise stroke counts with minimal maintenance, enabling reliable pump monitoring on land and offshore rigs.

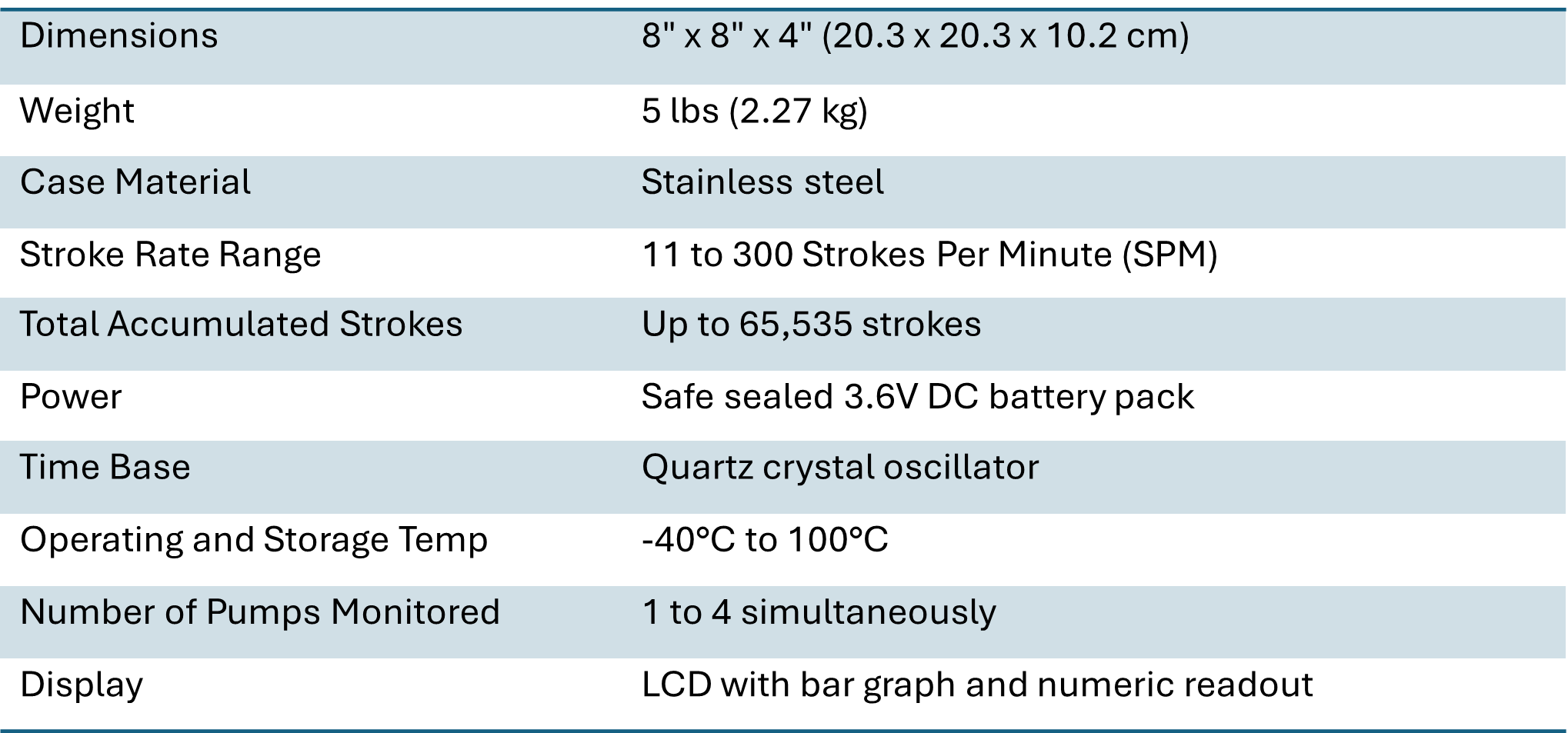

Technical Specifications

| Dimensions | 8" x 8" x 4" (20.3 x 20.3 x 10.2 cm) |

| Weight | 5 lbs (2.27 kg) |

| Case Material | Stainless steel |

| Stroke Rate Range | 11 to 300 Strokes Per Minute (SPM) |

| Total Accumulated Strokes | Up to 65,535 strokes |

| Power | Safe sealed 3.6V DC battery pack |

| Time Base | Quartz crystal oscillator |

| Operating and Storage Temp | -40°C to 100°C |

| Number of Pumps Monitored | 1 to 4 simultaneously |

| Display | LCD with bar graph and numeric readout |

Features and Benefits

- Real-time stroke rate updates every second.

- Monitors total strokes and stroke rate for up to four mud pumps simultaneously.

- Provides accurate, real-time data to optimize mud pump performance.

- Supports automated monitoring and control with remote outputs.

- Flexible mounting options simplify integration into existing control systems.

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

The HDI 2100 Pump Stroke Counter System is an electronic device designed to monitor mud pump performance in oil and gas drilling operations by accurately counting and displaying the number of strokes and stroke rates of up to four pumps simultaneously. Mud pumps play a critical role in circulating drilling fluids (mud) through the wellbore, and monitoring their operation is essential to maintain drilling efficiency, detect malfunctions, and ensure safe operation.

This system provides real-time stroke data updated every second, allowing operators to track pump activity precisely. It consists of a stainless steel control head with an LCD display, a power pack, cables, and sensors (either microswitch or proximity types). The control head can be mounted on a control panel either from the front or back, offering flexibility for installation in existing drilling consoles.

The internal quartz crystal oscillator guarantees accurate stroke counting without drift, meaning the system does not require regular recalibration, reducing maintenance needs. The system is powered by a sealed 3.6V battery designed to last approximately 18 months under continuous operation. Field-replaceable processor boards simplify repair and troubleshooting without needing to replace the entire unit.

Operating in harsh environments common to both land and offshore drilling, the 2100 features a sealed stainless steel case and durable piezoelectric switches for long life even under high vibration conditions. It supports integration with Human Machine Interfaces (HMI) and Programmable Logic Controllers (PLC) through dual sensor outputs, enabling automated monitoring and control within drilling systems.

The stroke rate range covers 11 to 300 strokes per minute, with the total accumulated strokes displayed up to 65,535. Operating temperature ranges from -40°C to 100°C, making it suitable for a wide range of drilling environments. The system’s combination of rugged design, accurate measurement, and flexible installation makes it a reliable tool for real-time mud pump monitoring critical to maintaining drilling safety and operational efficiency.

Engineering Data