HDI 2000B Pressure Gauge System

Pressure Gauge System

Also known as:

Solid-State Electronic Pressure Gauge, Rig Gauge

HDI 2000B Pressure Gauge System

Pressure Gauge System

Also known as:

Solid-State Electronic Pressure Gauge, Rig GaugeBuy

In Stock

Manufacturer

Price:

Request for QuoteShipping:

Air freightDelivery Time:

3 WeeksNote:

The HDI 2000B Pressure Gauge System is a panel-mount electronic gauge used to measure high-pressure levels up to 20,000 psi in industrial and oilfield environments. It connects to a remote sensor via interconnect cable for flexible, accurate pressure monitoring.Sign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Executive Summary

The HDI 2000B Pressure Gauge System is an electronic instrument used to accurately measure and display high-pressure levels in real time. It is typically installed on equipment such as wellheads, pumps, and manifolds in oil and gas or industrial settings—where maintaining safe and consistent pressure is critical to operations.

This panel-mounted system connects to a remote pressure sensor using an interconnect cable, allowing the display to be placed where it is most visible and accessible. It shows pressure readings up to 20,000 psi on a large LCD with both numeric and bar graph formats for quick and reliable monitoring. Designed for use in demanding field environments, the 2000B offers high accuracy (±0.50% of full scale), long battery life, and optional outputs to connect with control systems or remote displays. This system helps ensure equipment protection, process safety, and operational efficiency by giving clear, dependable insight into pressure conditions.

Technical Specifications

| Power | Battery powered |

| Pressure Range | 30 psi to 20,000 psi |

| System Type | Field repairable |

| Resolution | 10 psi |

| Connection Types | 2” Male NPT, 2” 1502, 2” 2002 / 2202, or flanged connections |

| Output Options | 4–20 mA or 0–1 VDC |

| Platform | Solid-state |

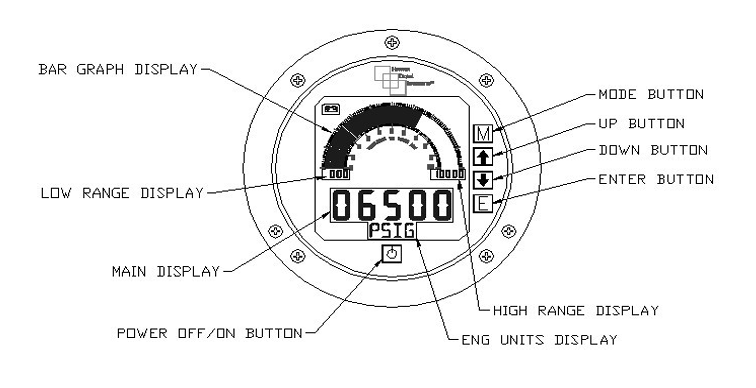

| Display | Analog bar graph with divided scale |

| Certification | ATEX / IECEx II 1 G, Ex ia IIC T4 |

| Vibration Resistance | Consistent performance in high-vibration environments |

Features and Benefits

- Measures up to 20,000 psi with ±0.50% accuracy.

- Compatible with various pressure connections and sensors.

- Integrates easily with control and monitoring systems.

- Flexible sensor and display placement for easier access.

- Modular design with remote sensor connected by interconnect cable.

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

The HDI 2000B Pressure Gauge System is a panel-mounted electronic device designed to measure and display high-pressure levels accurately in industrial and oilfield settings. It monitors pressures up to 20,000 psi with an accuracy of plus or minus 0.50 percent of full scale, making it suitable for critical applications where precise pressure monitoring is essential for safety and operational control.

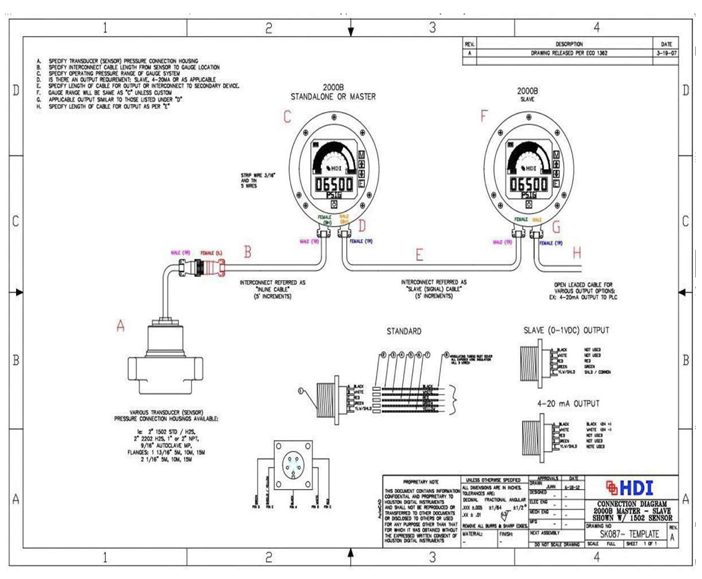

The system consists of two main components: a digital gauge display and a remote pressure sensor connected by an interconnect cable. This design allows the sensor to be installed directly at the pressure source, such as a wellhead, pump, or manifold, while the display is mounted in a more accessible location for easy reading and monitoring.

The gauge features a six-inch liquid crystal display that combines a five-digit numeric readout with an analog bar graph composed of 101 segments. This clear and detailed display makes it easy to quickly understand both the exact pressure value and its trend, even in low-light or harsh environments. The display can be read from up to 35 feet away.

Power is supplied by a replaceable 3.6-volt battery designed to last between 12 and 18 months under continuous operation. Calibration and configuration data are stored in memory that does not require power, ensuring settings remain intact even when the battery is replaced or the system is powered off.

The pressure sensor employs strain gauge technology and is compatible with a wide range of connection types including standard pipe threads and flanges. This allows the system to be used across various equipment and pressure ranges, while simplifying maintenance by enabling cross-compatibility of sensors.

Optional analog outputs provide 4–20 mA or 0–1 volt signals to connect the gauge to control systems, data loggers, or remote displays. This supports centralized monitoring and integration with automated process control.

In oil and gas operations, the 2000B system is commonly used to monitor pressure at wellheads to ensure safe extraction pressures, on pumps to maintain correct fluid flow and prevent overpressure damage, and on manifolds to track pressure differentials between flow lines. Accurate, real-time pressure data from this system helps operators detect anomalies early, avoid equipment failure, and optimize production rates while maintaining safe operating conditions. Its robust design and modular installation make it well-suited for harsh field environments where reliability and ease of maintenance are critical.

Engineering Data

More supplies and gear

Reference Information